All the ingredients for a Paperless Shop when you are ready

Use JobTrak to track parts, collect data, and sign off jobs with tablets.

Build process routers from preset tanks.

Build part routers from process routers.

Cascading changes ease maintenance.

Check the boxes for Nadcap and ITAR.

Upload pictures to the ITAR Cloud.

Build part routers from process routers

Works like your shop works

From quote to invoice – all bases covered.

Drag & drop parts on jobs just like racking.

Drop onto a shipper like packing in a box.

Preset certs with post-process edits.

Point & click fees for tests, expedite.

Drag & drop parts on jobs.

Option to run your shop with no paper routers or filing cabinets.

Use iPad or Android tablets for tracking jobs.

Sign steps and collect data on the tablet.

Simultaneous signoff of multi-part jobs.

Signoffs and data stored in database.

Point & click NCRs stored in database.

Sign steps and collect data on an iPad or Android tablet

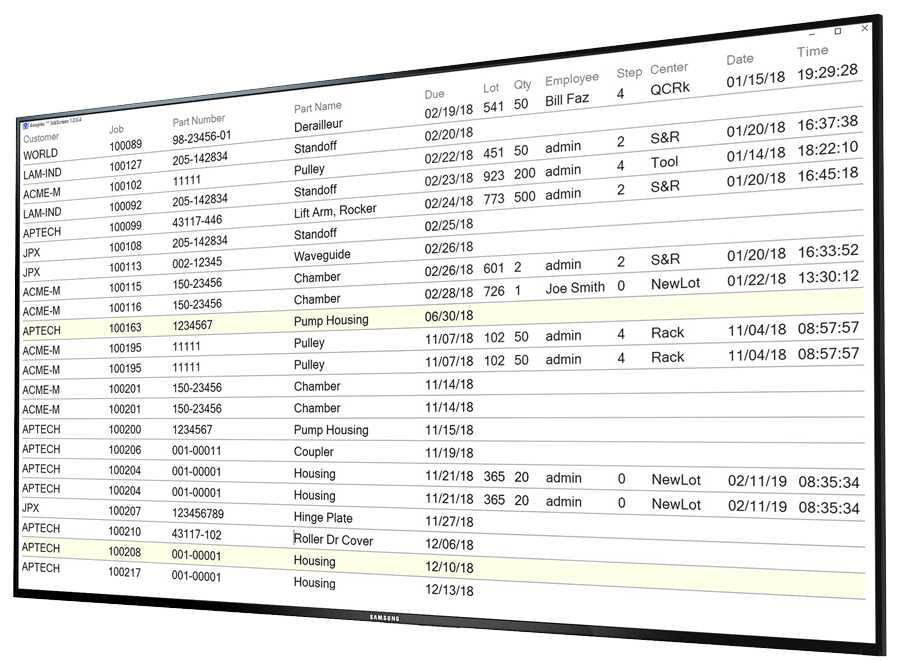

Job Scheduling & Tracking System

Jobs entered FIFO can be reordered to meet due dates.

Tools show shop job load by due date and process.

Progress bars show color-coded progress of each job.

Jobs show on monitors in the order to be processed.

Set up a monitor for every process line – no limits.

See scheduled job progress on wall-mounted monitors

More money to your bottom line.

No upfront cost. Free trial with no obligation.

No per-user fees or other hidden costs.

FREE online training.